With the development of modern buildings to lightweight, high strength, high-rise, large span, higher performance direction and the deterioration of the use environment, the strength of concrete used in engineering will become more and more high. Compared with ordinary concrete, high strength concrete can greatly improve the strength of concrete, reduce the weight of the structure, improve the durability of concrete, reduce the amount of materials, reduce the cost of the project and save space. In some developed countries, high-strength concrete has been used quite widely. In recent years, China's high-strength concrete development is very rapid, C50~C70 concrete has been widely used in practical engineering, C=80~C100 concrete has begun to be used in engineering. At present, the preparation technology of high strength concrete is mainly realized by adding highly effective water reducer and active mineral admixture. In this experiment, local conventional raw materials were used to equalMicro Silicone PowderIn order to determine the optimum mix ratio, the influence of water glue ratio, silica ash content, high efficiency reducer content and sand rate on the strength of high strength concrete was formulated by replacing the equivalent sand with the external blending method, so as to establish a reliable basis for realizing the economy and popularization of the strength concrete.

In this paper, using conventional raw materials and general technology, the equivalent of micro-silica powder instead of the same amount of sand, that is, the design test of external blending method, the use of high-efficiency water reducer and micro-silica powder method for the preparation of high-strength concrete. The effects of the use of cemented materials, the ratio of water glue, the amount of reducing agent, the sand rate and the amount of silica powder on the compressive strength of high strength concrete were studied, and the optimum mix ratio was obtained.

1 Test conditions

1. 1 Raw Materials

1) Cement: No. No. 625 silicate cement, 28d compressive strength 71.7 MPtt, other performance indicators are in line with GB175-1999.

2) coarse aggregate: 5mm~40mm grade with good natural pebbles, apparent density of 2.74g/cm3, stacking density of 1 490kg/m3, crushing index of 1.9%, needle, flake particle content of 4.1%.

3) fine aggregate: Natural river sand, apparent density of 2.68g/cm3, stacking density of L 650KG/M3, fineness modulus of 2.8, medium sand.

4)Zirconium Silica Powder: Quanzhou Industrial Co., Ltd. production.

5) Water reducer: FDN 12 type high efficiency water reducer.

1. 2 Pilot Scheme

The use of external blending method, that is, the equivalent of micro-silica powder instead of the same amount of sand design test, the use of 16 high-strength concrete mix ratio, strength grade range of c60~c80, specimen size of mmx150mrnx150 mm, in accordance with national standards molded concrete specimens, under the standard maintenance conditions, maintenance to 28d age, Test the compressive strength of concrete.

2 Test results and analysis

2. Effect of 1 cemented material dosage on compressive strength of high strength concrete

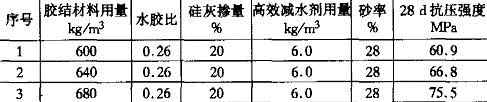

The effect of the dosage of three kinds of cemented materials on the compressive strength of high strength concrete in l600 kg/m3,640kg/m3,680kg/m3 was studied. The test results are shown in table 2 and Figure 1. As can be seen from Figure 1, the compressive strength of concrete increases when the amount of cemented material is increased. This is because when the water glue ratio is constant, increasing the amount of cemented material increases the compactness of the concrete.

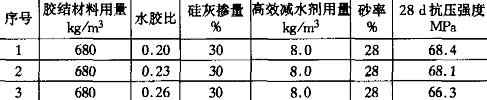

Table 2 Effect of cemented material dosage on compressive resistance of high strength concrete

Fig. 1 Effect of cemented material dosage on compressive strength of high strength concrete

2. Effect of 2 water glue ratio on compressive strength of high strength concrete

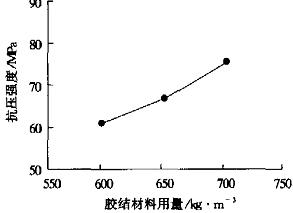

Water glue ratio is the basic factor affecting the strength of concrete. According to the experimental study, the water ash ratio theorem is also suitable for high strength concrete. Therefore, the water glue ratio of less than 0.30 is used in this experiment, that is, the test is carried out with 0.20,0.23,0.26 three water glue ratio, the results are shown in table 3 and Figure 2.

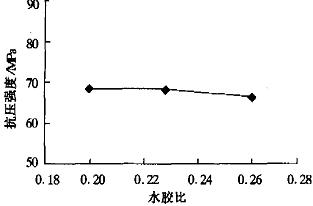

Table 3 effect of water glue ratio on compressive strength of high strength concrete

Table 3 effect of water glue ratio on compressive strength of high strength concrete

Fig. 2 The influence of water glue ratio on the compressive strength of high strength concrete

As can be seen from Figure 2, when the amount of cemented materials is certain, with the water glue ratio to reduce the compressive strength of concrete increased.

2. Effect of 3 efficient water reducer dosage on compressive strength of high strength concrete

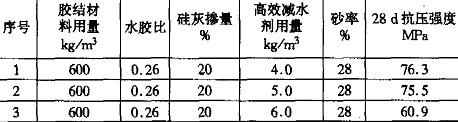

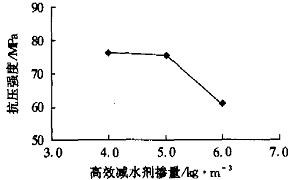

The test adopts No. No. 625 Cement, the amount of cemented material is 600kg/m3, the amount of silica powder is 20%, the water glue ratio is 0.26, the content of high efficiency reducer is 4KG/M3~6KG/M3, and the test results are shown in table 4 and Figure 3. It can be seen that with the increase of the amount of water reducer, the strength of concrete decreases, and after the dosage exceeds 5kg/m3, the intensity decreases greatly.

Table 4 Effect of high efficiency water reducer dosage on compressive strength of strength concrete

Fig. 3 Effect of high efficiency water reducer dosage on compressive strength of strength concrete

2. Effect of 4 sand rate on compressive strength of high strength concrete

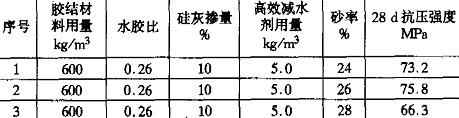

Table 5 Effect of sand rate on compressive strength of high strength concrete

Fig. 4 Effect of sand rate on compressive strength of high strength concrete

The test used cemented material dosage of 600kg/m3, water glue ratio 0.26, sand rate 24%~28%, the test results are shown in table 5 and Figure 4. It can be seen that with the increase of sand rate, the strength of concrete increases, but after the sand rate exceeds 26%, the strength of concrete decreases.

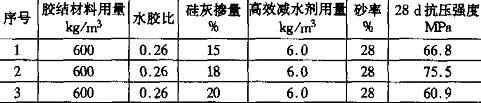

Table 6 effect of micro-silica powder dosage on compressive strength

Fig. 5 Effect of micro-silica powder dosage on compressive strength

2. Effect of 5 micro-silica powder dosage on compressive strength (see table 6 and Figure 5)

The dosage of 15%,18%,20% three kinds of silica powder was used in the experiment. With the increase of the amount of silica powder, the strength of concrete increases significantly, but when the amount of silica powder is more than 18%, the intensity reduction is also very large.

3 Conclusion

1) The use of conventional raw materials and general technology, mixed with high-efficiency water reducer and micro-silica powder preparation of strong-strength concrete, can make full use of local raw materials, access to good economic high-strength concrete.

2) Preparation of high-strength concrete, when the water glue ratio is less than 0. 23 o'clock, even the addition of a large number of high-efficiency water reducers can not increase the strength of concrete. Therefore, the suitable water glue ratio range for the preparation of high strength concrete is 0.23~0.30.

3) under the condition that the water glue ratio is certain, the compressive strength of concrete increases with the increase of the amount of micro-silica powder. But when the water glue is more than an hour, the activity of micro-silica powder does not play out, which has a significant effect on the compressive strength of concrete. Therefore, the suitable silica ash content for the preparation of high strength concrete is 15%~25%.

4) under the condition that the water glue ratio is certain and the collapse degree is the same, the compressive strength of the concrete with small dosage reducer is high. When the amount of high efficiency water reducer exceeds 9 kg/m3, the compressive strength of concrete remains almost unchanged. Therefore, the amount of suitable high efficiency water reducer for the preparation of strength concrete is 5 kg/m3~7 kg/m3.

5) Increasing the sand rate can improve the compressive strength of concrete. Therefore, the sand rate of 20%~30% is more suitable when preparing high strength concrete.

Related Industry Knowledge

- Study on mix ratio of high strength lightweight concrete silicon powder in highway bridge

- Application and sales of micro silica powder in building materials industry

- Prevention of the reaction of micro silica powder to concrete alkali aggregate

- Effect of micro silica powder on cement performance

- Microsilica is an important factor affecting the performance of refractory castables

- Preparation of high-purity nano-SiO2 powder from waste micro-silica powder

- Microsilica and silicon micropowder market phenomenon

- Micro silicon powder industry implementation standards

- Method for producing nano silicon powder